Our Technologies

At Plastopil, state-of-the-art processes ensure quality, efficiency, and innovation in every product we create. Discover what powers our flexible packaging solutions, from raw materials to finished products.

Extrusion

Our advanced extrusion technology transforms raw plastic materials into high-quality films with precise thickness control and superior barrier properties. This process forms the foundation of our flexible packaging solutions, ensuring consistent quality and performance across all applications.

Solvent-Less Lamination

Our environmentally-friendly solvent-less lamination process bonds multiple layers without harmful solvents, creating superior barrier properties while maintaining food safety standards. This technology ensures strong adhesion and excellent performance in demanding applications.

Precision Pouch Making

Our automated pouch-making equipment transforms printed and laminated films into finished packaging with precise sealing and cutting. Advanced quality control systems ensure consistent dimensions, seal integrity, and optimal performance for various product applications.

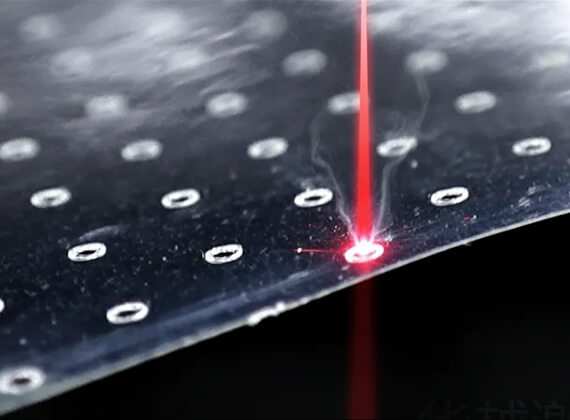

Laser Perforation

Precise laser perforation technology creates controlled ventilation and easy-open features in packaging materials. This advanced process ensures consistent hole patterns and optimal breathability for fresh produce and other applications requiring controlled atmosphere packaging.

Advanced Printing

State-of-the-art flexographic and digital printing technologies deliver vibrant, high-resolution graphics that enhance brand visibility and product appeal. Our printing capabilities ensure consistent color reproduction and superior print quality across all packaging formats.

Innovation and Development

We continuously push boundaries of flexible packaging technology to develop next-gen solutions that meet evolving market demands and maintain environmental responsibility.

Quality

Above All

Every product that leaves our facility meets or exceeds industry benchmarks for safety, performance, and reliability.

ISO 9001

Certified quality management system ensuring consistent processes, continuous improvement, and customer satisfaction across all operations.

BRC Global Standard

British Retail Consortium certification guaranteeing the highest levels of food safety and quality in packaging manufacturing.

HACCP

Hazard Analysis Critical Control Points system ensuring food safety through systematic identification and control of potential hazards.